Cogeneration Using Pyrogasification of Wood Biomass

CCE OIL

Sustainable development and the need for clean energy often are a battlefield as it combines contrasting interests. It is taking that into consideration that we have developed a system capable of cogenerating, starting from virgin wood resulting from forest management and end with electricity and heat without producing air pollution.

Thanks to its small size this system can be deployed in the vicinity of the raw materials needed to operate it, wooded areas, thereby relocating the production of energy and guaranteeing added value to areas seeking new development, as well as a significant reduction in both transportation costs and as well as supply costs.

The plant is designed to operate 24/7, and is equipped with the innovative technology of pyrogasification based on the construction technique of simplified dual-stage gas that uses air as an fluidizing component (Patent no. 0001415899).

This new patented technology has enabled us to re-start wood biomass systems of other companies and to design and implement our complete plant. The organic material (the wood) is transformed first into a raw substance and is saturated with powder, syngas. Subsequently it is cooled and purified, optimizing it for operating the engines. The whole plant produces no emission but the values of the drains of the engines, fall within the prescribed limits of the Law, DL 152/06. The value of fine dust emissions PM10, is reduced up to 20 times lower than that of a typical pellet boiler of equal thermal power.

The maximum size of the plant available is 200 kW; the organic material consumption, 35-37% humidity (the plant dries the wood autonomously up to 10-12%), and consumes about 1,500 tons per year for the 200 kW system. The modular design facilitates installation and maintenance, while an insurance guarantee eliminates the risk of malfunctions.

Subsidies on Ministerial Decree of 6th July 2012 and 23rd June 2016 DMiSE

The cogeneration plant described herein falls into the category of plants subsidized by the Ministerial Decree of 6 July 2012 and by the subsequent Decree of the Ministry of Development of 23 June 2016. The decrees determine the method of subsidizing the production of electricity from plants powered by renewable sources; the expected subsidy has a duration of 20 years and currently has a basic subsiding tariff (Tb) of 246 € / MWh (DMiSE of 23 June 2016). For plants that come into operation by 30 June 2017 shall be also provided for any awards (Pr), such as reducing emissions (30 € / MWh) high-efficiency cogeneration (10 € / MWh), use thermal energy for district heating (40 € / MWh) (DM July 6, 2012).

Internal consumption of electric energy

The subsidies are recognized on the net production of electricity produced by the plant. The net production injected is the value between the net output of the plant and the self-consumption (set by the DM July 6, 2012 as a fixed value to 17%). The plant has an increasingly self-consumption of less than 17% and it is possible to use this energy itself / or to dispose of the portion of the electrical energy not subject to the subsidy.

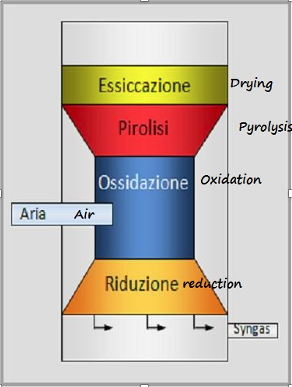

Principle of Operation of the Pyrolysis Reactor, Pat. 0001415899

The innovative part of the entire system is the Pyrolysis Reactor, which has enabled us to reactivate inactive and / or malfunctioning plants and this technology can also be used to design complete plants. The Pyrogasification used is commonly referred to as “down-draft”. This type of Pyrogasification consists of a closed tank in slight depression in which wood chips are introduced from above. Both the product gas (commonly referred to as syngas) and ashes extracted from the bottom of the reactor.

The Material Falls from the Top Downwards Because of Gravity.

During the descent the following reactions occur:

Oxidation

In its descent within the Pyrogasification the Pyrolysis products enter a narrowing area in which a specific amount of air is injected . In this area a part of the tar and charcoal are burned at temperatures above 1000 ° C. This reaction provides the heat necessary for the reactions to occur in the remaining areas of the pyrogasification. This type of pyrogasification guarantees an extremely low tar content in the syngas, in fact the tar generated in the pyrolysis is almost completely decomposed through the oxidation compartment. This compartment is very narrow and the temperature is very high.

Reduction

In this area the charcoal, supported by a grid, reacts with the gases coming from the oxidation compartment that retains temperatures above 700 ° C. The reactions that occur in this area allows results in the production of combustible gases (mainly CO and H2), transforms the water vapor coming from the drying and oxidation stages. This results in the production of carbon dioxide which is generated in the oxidation compartment and the charcoal.

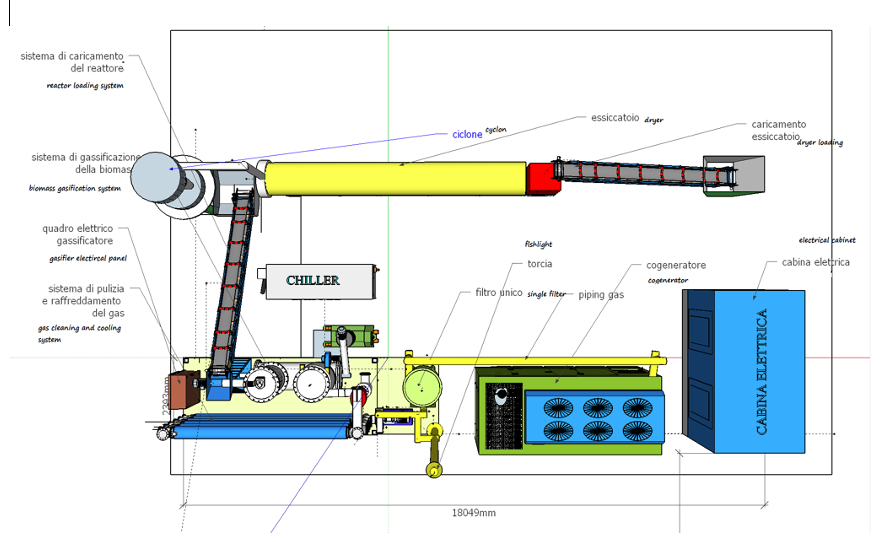

The cogeneration Plant

Simplified Two-stage Pyrogasification Producer capable of producing syngas in sufficient quantities to power an electric generator for about 200 kWe and 200 kW thermal systems.

Filtration System, cooling and cleaning of the produced gas.

Full Engine Electric Generator, Alternator, approximately 200 kW, in cogeneration with the motor-driven water return and waste gases with the production of hot water at 70/80° C.

Electric Generator Casing, ensuring a sound proof standard of 65 decibels (optional 45 decibels).

MV/LV Transformer into resin from 100 kVA.

Pyrogasification Control Panel.

Control Panel and parallel panel of the cogenerator made as per 0-16 regulations module and complete with tax counters.

- Heat Recovery Units (primary air/air heat exchanger designed to power a drying plant).

- Storage and transport of biomass system with automatic loading into the reactor.

Biomass Drying System of about thermal 30 w.

Simplified Two-stage Pyrogasification Producer:

Wood biomass powered gasification reactor.

- Treatment capacity of about 100/125 kg/h (quantities are proportional to the power plant and the biomass used).

- Fluidifier method: air.

- Filtration system, including: blast chiller, Cyclone separator, Scrubber Venturi, final exchanger with Drop-stop, cooling Chiller and everything else needed to obtain the syngas to be sent to the engine.

200 kW Cogeneration Electrical Generator Housed in a Soundproof Casing.

The Generator is driven by an Otto Cycle Engine suitable for operation with gases poor in output of 200 kW will be provided among the models produced by the major manufacturers of gas engines. The choice of the generator will be defined after the site survey, humidity and average composition of chips that will be used and, before signing the contract for the supply of the system.

Parallel switchboard:

The Parallel Switchboard will be installed and connected to the edge of the generators on site. They will be tested and verified for all parallel operations, including:

- Operational command, control and signalling circuits of the electrical generator placed on one single board with the possibility of remote control.

- Circuit breaker and parallel.

- Interface protection for parallel grid.

Transformer cabinet:

Electrical cabinet will be provided with a; 100 kVA transformer LV/MV, LV, BT delivery panel, MT panel offering protection and General device.

The cabinet will be made of metal and will be divided into “local user”, local transformation.

Tax counters:

Tax counters must count the energy produced in order to obtain comprehensive incentive tariffs.

Review and possible adjustment of the transformer cabinet:

It is expected that adjustment and modifications of the user’s transformer cabinet will be necessary both if the user already has a cabinet and he event that the cabinet must be made ad hoc.

The plant fed with solid biomass is designed for 24/7 operation. The plant is guaranteed to run for at least 7,500 hours per year, considering downtime for a variety of reasons.

The power of the plant depends on both the moisture and the size of the chips. The relationship between relative humidity and plant power may vary according to decreasing moisture values, taking as a basis for calculation, relative humidity of 20%. The power supply must use “chips” between 35 mm and 50 mm with a tolerance of +/-20% and a maximum humidity of 35% – 37%.

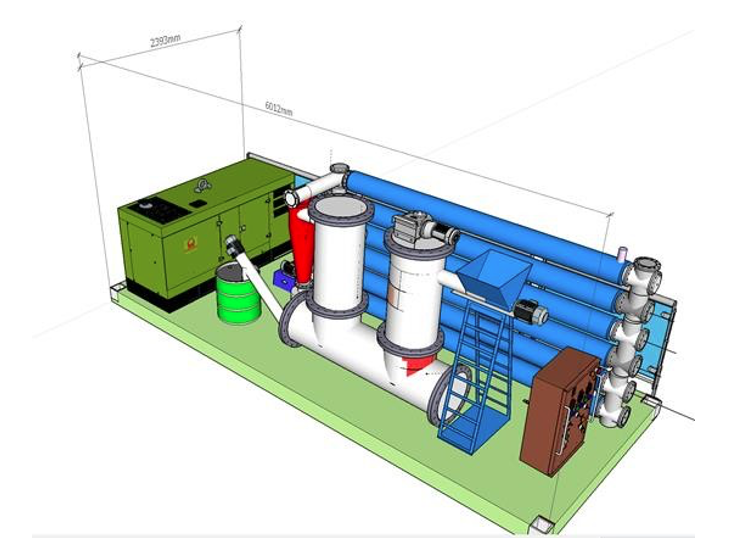

Approximate size: 2,393 6,012 mm x mm

Warranties of Operation

The plant will be carried out in full compliance with all current regulations, with the use of top quality materials and features and having the utmost care in installation and in various connections.

To ensure perfect operation of the system, we follow the project authorization from authorization requests to testing, from collaboration for all-risk insurance contract (including compensation for loss of production for failure) until the scheduled and extraordinary maintenance of the plant.

- Complete service on all the administrative and/or authorization.

- Preliminary surveys.

- Planning and construction management.

Technical Assistance:

- Assistance on site for fireproof works.

- Connection to Enel cabin.

Testing and Activation of the Plant:

- Full service support and maintenance services.

- Warranty.

- All-risk insurance.

Testing:

The biomass plant will be tested for activation as temporary testing. The final testing shall take place at the end of the two years required by law. The certificate will contain the end date for testing.

Commissioning of the Plant:

Our technicians will be present until the commissioning of the plant with consequent delivery of electricity to the network operator, and for training and education of the plant stuff, until the test cycle is completed.

Full Service Support and Maintenance Services:

Specific service agreement on ordinary assistance and maintenance that includes scheduled interventions to the pyrogasification, to the electric generator, all parts and components subjected to wear and tear and/or replacement, regular analysis of syngas and motor oil.

Delivery and Warranty:

The delivery of the generators is 120 days from the payment of the deposit; delivery and installation of the complete system is made within 30 days of delivery of the generators. Plant warranty is two years.

All-risk Insurance:

The system is combined with an “all risk” insurance policy with Generali Italy Spa called, Generaenergia / insurance for equipment for the production of energy from renewable sources, including compensation for fires, breakdowns, RCTO, theft and especially damage from interruption of operation, covering the lack of production of energy and therefore the non-collection of the tariffs.

Economic Advantages of the Project/income Hypothesis

The construction of a Cogeneration Plant in Syngas from gasification of wood chips allows an average annual financial returns of 20%, if it is not desirable to use the thermal energy produced (either as a sale, both as a substitute not used to other heat source). Optimal performance is achieved clearly using the heat energy produced.

Indicative performance table without using thermal energy with DM 6/07/2012-inclusive tariff and DMiSE 6/23/2016

kW/h produced | Approximative investment | Approoximative performance with DM 6/07/2012* | Approximative performance with DMise 23/06/2016** |

198 | About € 780,000.- | About 27.4% | about 20.6% |

* Indicative Annual Return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables in the business plan):

- -Inclusive tariff with plant before 6/30/2017: € 0.286 kW·h basic fee: € 0.246 kWh.

- Award reduced emissions: € 0.030 kW/h.

- High-efficiency cogeneration basic award: 0.010 kW·h.

** Indicative annual return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables business plan):-inclusive tariff with plant after 6/30/2017: € 0.246 kWh.

- basic fee: € 0.246 kWh

- operating hours per year: 7,500 hours.

Average cost of wood chips with a moisture of 40%: € 60/Mt.

References

Early versions of the Pyrolysis Reactor dating back to 2015, had incidents of malfunctioning power plants installed by other companies in Lazio and Piedmont. These stations were Initially used as experimental test systems and then became fully functional and networked in 2016. The complete V2 plant was a result of these experiences gained with the early Pyrolysis Reactor. The changes in pyrolysis reactors V0 and V1 were therefore direct results of the earlier experiences and has evolved using innovative technologies resulting from these improvements and changes.

BELOW: Today the 200 kW Plant in Cassino (Frosinone), is already operational utilizing the new Pyrolysis Reactor (installed in 2016) while in January 2017 work started on the complete 200 kW Plant in Colle Umberto (Treviso).

Cassino (Frosinone), iTALY

V1 200 kW Plant

BELOW: V2 200 kW Plant Under Construction in Colle Umberto (Treviso), Italy.

Economic Advantages of the Project/income Hypothesis

The construction of a Cogeneration Plant in Syngas from gasification of wood chips allows an average annual financial returns of 20%, if it is not desirable to use the thermal energy produced (either as a sale, both as a substitute not used to other heat source). Optimal performance is achieved clearly using the heat energy produced.

Indicative performance table without using thermal energy with DM 6/07/2012-inclusive tariff and DMiSE 6/23/2016

|

kW/h produced |

Approximative investment |

Approoximative performance with DM 6/07/2012* |

Approximative performance with DMise 23/06/2016** |

|

198 |

About € 780.000.- |

About 27,4% |

about 20,6% |

* Indicative Annual Return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables in the business plan):

- -Inclusive tariff with plant before 6/30/2017: € 0.286 kW·h basic fee: € 0.246 kWh.

- Award reduced emissions: € 0.030 kW/h.

- High-efficiency cogeneration basic award: 0.010 kW·h.

** Indicative annual return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables business plan):-inclusive tariff with plant after 6/30/2017: € 0.246 kWh.

- basic fee: € 0.246 kWh

- operating hours per year: 7,500 hours.

Average cost of wood chips with a moisture of 40%: € 60/Mt.

Economic Advantages of the Project/income Hypothesis

The construction of a Cogeneration Plant in Syngas from gasification of wood chips allows an average annual financial returns of 20%, if it is not desirable to use the thermal energy produced (either as a sale, both as a substitute not used to other heat source). Optimal performance is achieved clearly using the heat energy produced.

Indicative performance table without using thermal energy with DM 6/07/2012-inclusive tariff and DMiSE 6/23/2016

|

kW/h produced |

Approximative investment |

Approoximative performance with DM 6/07/2012* |

Approximative performance with DMise 23/06/2016** |

|

198 |

About € 780.000.- |

About 27,4% |

about 20,6% |

* Indicative Annual Return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables in the business plan):

- -Inclusive tariff with plant before 6/30/2017: € 0.286 kW·h basic fee: € 0.246 kWh.

- Award reduced emissions: € 0.030 kW/h.

- High-efficiency cogeneration basic award: 0.010 kW·h.

** Indicative annual return on total investment before taxes net of borrowing costs. Other key parameters (for further information see tables business plan):-inclusive tariff with plant after 6/30/2017: € 0.246 kWh.

- basic fee: € 0.246 kWh

- operating hours per year: 7,500 hours.

Average cost of wood chips with a moisture of 40%: € 60/Mt.